With compact structure design and well thought out machine concept remarkable detailed design and the perfect coordination of the individual components to ensure the perfect finishing.

N.W

Power

Packing size

| Model | G560 |

|---|---|

| Panel length | Min70mm |

| Panel width | Min80mm |

| Panel thickness | 12-50mm |

| Edge thickness | 0.4-3mm |

| Feeding speed | 8m/min |

| Air pressure | 0.6Mpa |

| N.W | 560KG |

| Power | 6.18kw |

| Oversize | 2625*1315*1315mm |

| Packing size | 2200*725*1248mm |

Control panel with 7”touch screen

Easy ,self-explanatory representation of the units and their functions,

error message show on the screen .

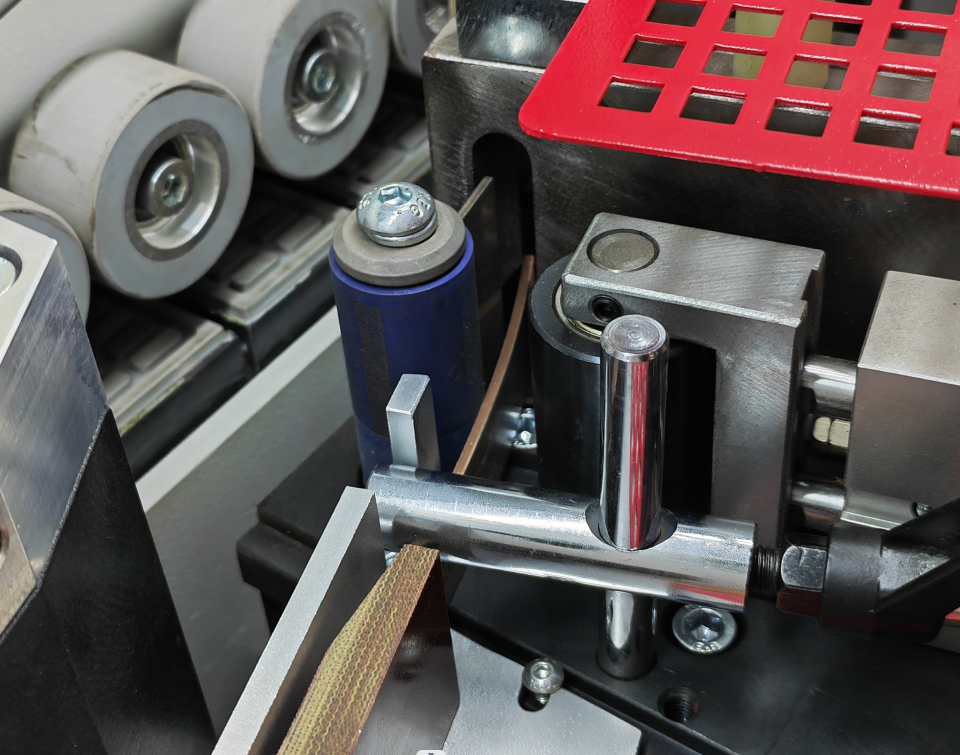

Pre-milling unit

The two diamond tipped spindle heads rotate in opposing directions

ensure a perfectly straight .workpieces edge ,to which before the edge

material can be glued .

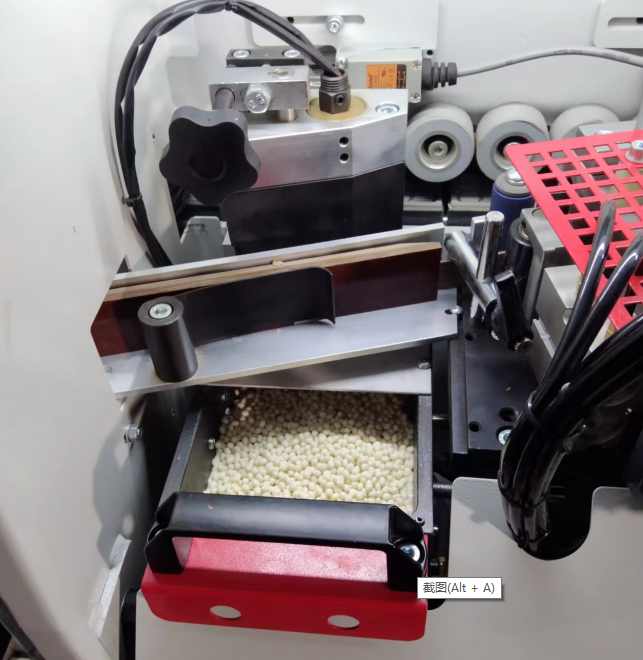

Edge feed and guillotine scissors

Coiled material 0.4-2mm thick can be used for workpieces up to

43mm in the thickness .

Glue pot unit

The edgebander require only 15minutes to reach operate temperature ,

with the Teflon coated glue pot and quick change system.

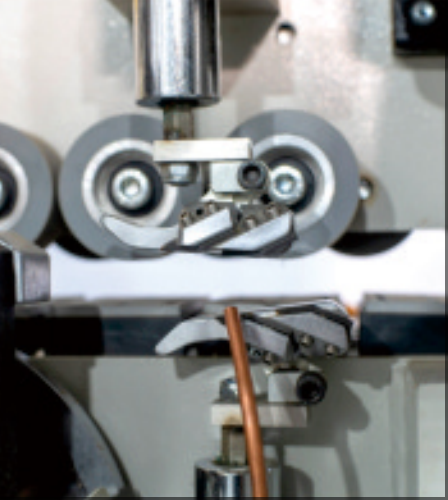

Pressure rollers

The roller press the edging to the workpieces.The adjustable control

prevent the glue from smearing and edging tape from being “squashed”.

End trimming unit

The end cutting with 2 independent saw,with one high frequency

motor running at 12000rpm .Linear guidance ensures the highest

level of precision .

Fine trimming unit

With two independent trimming unit with two high frequency motor

running at 12000rpm,2mm radius tools are included as standard ,

also can be equipped with 3mm radius tools.

Flat scraping Unit

It is used to eliminate the ripplemarks caused by the cutting pr-ocess of

the non-linear movem-ent of trimming process, so theboard finish of

upper and lowerparts is tidier and more smooth

We will contact you within 24 hours